Toward Sustainable, Digital and Economical Solutions

KFUPM – Dhahran, KSA Feb. 17-19, 2024

As the E&P industry transitions itself towards a more sustainable future and a net zero carbon outlook, it seeks innovative technological breakthroughs to ensure the smooth and efficient operation of oil and gas production facilities. The existing models of flow assurance solutions need to be revisited to adapt the industry direction for sustainable energy production as well as economic profitability. This technical symposium at the KFUPM main campus in Dhahran, Saudi Arabia, covers major flow assurance and production topics.

Flow assurance and production optimization require a deeper understanding of chemical, physical, and thermodynamic coupled phenomena that occur during the injection and production of complex fluids. The event is a highly anticipated gathering of experts and professionals in the oil and gas industry. It will link industry professionals and university academicians from diverse but complementary and field-relevant backgrounds. The event aims to provide a platform for industry experts, researchers, academics, and students to exchange knowledge, ideas, and experiences on the latest developments, challenges, and best practices in the field. As such, the event is expected to attract a diverse audience from the upstream oil and gas industry, chemicals manufacturing industry, and other related fields, including professionals, government representatives, academics, researchers, and students from around the globe.

The event will cover a wide range of topics including flow loop and sensing technologies, multiphase flow and metering, fluid mechanics, drilling fluids, cuttings transport, heat transfer, corrosion, gas condensate, gas hydrates, scale formation, wax deposition, and asphaltene management. The workshop will also focus on new technologies, tools, and techniques (e.g., sensors, robotics, and machine learning) for optimizing production processes and reducing operational costs and carbon emissions. It is an excellent opportunity for attendees to gain insights into new research and development initiatives in the industry, learn about the latest trends and challenges, and network with peers and industry subject matter experts (SMEs).

The 2-Day event will feature keynote speeches, technical presentations, a panel session, and poster sessions with ample networking opportunities. Attendees will have the opportunity to share knowledge at technical sessions by distinguished speakers and poster sessions by aspiring students. They will also work together to identify the major operational and technical challenges at breakout sessions, explore new and potential methodologies to address some of the key issues at panel sessions, and potentially uncover hidden opportunities to collaborate and deliver solutions that take the industry into the next energy evolution.

Post-event objectives will include issuing a call for proposals on the identified industry grand challenges in this field. Proposals will be jointly submitted to the industry with in-kind match funding from KFUPM.

Organizing Committee

Mazen Kanj

CPG-KFUPM Consultant

Kiran Gawas

Halliburton

Mohammed Al-Hamad

SLB

Abul Jamaluddin

EnerGenix Consulting

Shirish Patil

KFUPM

Mohamed Mahmoud

KFUPM

Rahul Gajbhiye

KFUPM

Abdelsalam Alsarkhi

KFUPM

Abdullah Sultan

KFUPM

Jarvis Cline

KFUPM

Rodwan Zweit

ARAMCO

Event Contributors

Oliver C. Mullins

SLB

Bastian Sauerer

SLB

Emmanuel Giannelis

Cornell University

David Yue

Halliburton

Sibani Biswal

Rice University

Carolyn Koh

Colorado School of Mines

Harvey Yarranton

University of Calgary

Mohamed Mady

Qatar University

Simon Davies

Worley

Ahmed Ali

SLB

Srdjan Nesic

Ohio University

Gordon Graham

Scaled Solutions Ltd.

Brian Kinsella

Curtin University

Cem Sarica

University of Tulsa

Eissa Al-Safran

Kuwait University

Ibnelwaleed Hussein

Qatar University

Muhammad Arsalan

ARAMCO

Rigoberto E. M. Morales

UTFPR, Brazil

Saad Mutairi

ARAMCO

Yermek Kaipov

SLB

Zain Yamani

KFUPM

Maarten de Hoop

Rice University

Milind Deo

University of Utah

Mohammad Aziz Rahman

TAMUQ

Registration

The Flow Assurance Technology Symposium, 2024, consists of two parts with separate registration.

Please register for one or both components below.

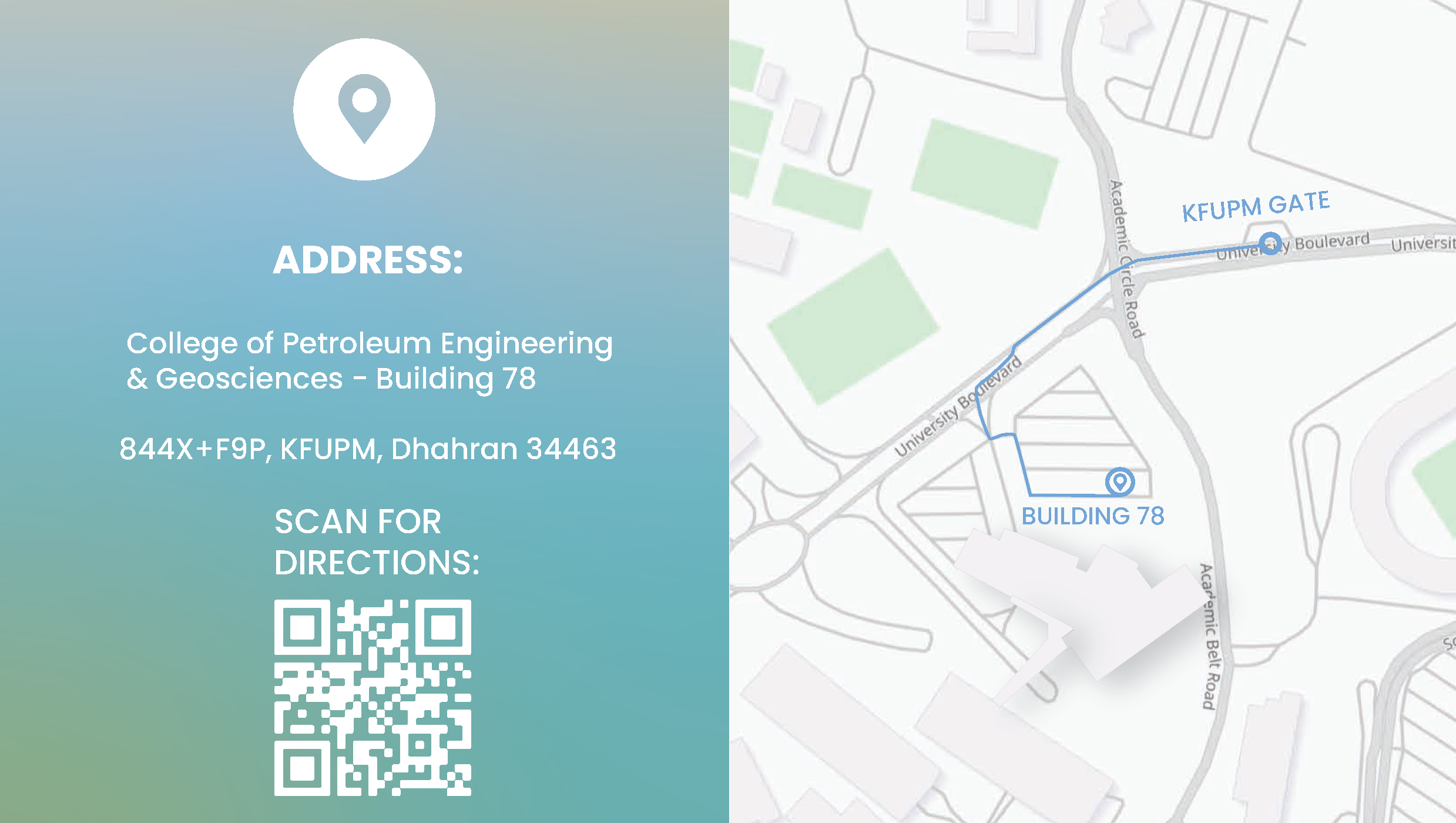

The venue is Building 78 within KFUPM campus. Click the image below for directions.

Program Details - February 18th - 19th

FEBRUARY 18TH

Summary

An engaging series of technical talks, across four sessions, will overview the latest technology innovations and opportunities in the fields of production chemicals, organic solids, scales & corrosion, and multiphase flow. A mid-day poster session provides time for networking and reviewing the latest work from Ph.D. students and postdoc researchers from research groups around the world. The sessions provide a basis for the discussions of the following day.

08:00 - 08:30

Introduction

08:30 - 10:00

Technical Session -

Production Chemicals for Enhanced Flow Assurance – Harnessing the Power of the Digital Space and the Molecular Scale

Co-Chairs: Mohammed Al-Hamad (SLB), Kiran Gawas (Halliburton)

08:30 - 08:50

Recent trends in Production Chemistry - Sustainability and Digital Aspects

Bastian Sauerer (SLB)

08:50 - 09:10

Targeted and Delayed Delivery of Chemicals in Oil Reservoirs

Emmanuel Giannelis (Cornell University)

09:10 - 09:30

Scale Control Challenges in US Shale Production

David Yue (Halliburton)

09:30 - 09:50

Application of Nanofluids to Remediate Asphaltene Deposition

Sibani Biswal (Rice University)

10:00 - 11:00

Technical Session -

Flow Hindrance Due to Precipitation and Deposition of Organic Solids

Co-Chairs: Abul Jamaluddin (EnerGenix Consulting), Shirish Patil (KFUPM)

10:00 - 10:20

Interfacial Controls in Gas Hydrate Flow Assurance Management

Carolyn Koh (Colorado School of Mines)

10:20 - 10:40

Some Insights from Asphaltene Flow Assurance Fundamentals

Harvey Yarranton (University of Calgary)

10:40 - 11:00

Environmentally Acceptable Phosphonates For Oilfield Scale Management

Mohamed Mady (Qatar University)

11:00 - 11:30

Opening Ceremony under the patronage of Dr. Muhammad Al-Saggaf, KFUPM President

11:30 - 13:30

Lunch & Poster Session

13:30 - 15:00

Technical Session -

Scales and Corrosion in The Oil and Gas Industry

Co-Chairs: Rahul Gajbhiye (KFUPM) and Ibnelwaleed Hussein (Qatar University)

13:30 - 13:50

Dense Phase Corrosion of Carbon Steel in CO₂ Transportation (Online)

Srdjan Nesic (Ohio University)

13:50 - 14:10

Single Step Sulfate Scale Removal

Mohamed Mahmoud (KFUPM)

14:10 - 14:30

Advances in Understanding Fluid Flow Dynamics and the Kinetics

Associated with Surface Scaling

Gordon Graham (Scaled Solutions Ltd.)

14:30 - 14:50

Chemical and Mechanical Properties of Oilfield Corrosion Inhibitors - Treatment of Under Deposit Corrosion

Brian Kinsella (Curtin University)

15:00 - 16:30

Technical Session -

Modeling and Experimentation of Multiphase Flow: Slugging, Metering, and Transportation for Empowering the Economic, Environmental, and Digital Solutions

Co-Chairs: Yermek Kaipov (SLB), Abdelsalam Alsarkhi (KFUPM)

15:00 - 15:20

A Discussion on Flow and Flow Assurance of the Transport and Injection of CO₂ and Impurities

Cem Sarica (University of Tulsa)

15:20 - 15:40

Eissa Al-Safran (Kuwait University)

15:40 - 16:00

Unmasking the Mystery: Demystifying Multiphase Metering Challenges and Breakthroughs

Muhammad Arsalan (Saudi Aramco)

16:00 - 16:20

Experimental Characterization of Horizontal Two-Phase Slug Flow with High Density Gases

Rigoberto Morales (UTFPR - Federal University of Technology, Paraná)

FEBRUARY 19TH

Summary

The second day program provides a unique opportunity for an open discussion among a leading group of attending experts and technology innovators. This moderated forum is targeted to identify challenges, rank those challenges, and brainstorm potential solutions with an eye towards industry-academia partnerships. Distinguished discussion leaders will structure the conversation while taking collective notes and the day’s findings will be summarized and presented at the wrap-up session.

08:00 - 09:30

Panel Session -

Navigating the Future of Flow Assurance: A Panel Discussion Addressing the Challenge Areas of Today and the Technology Readiness for Tomorrow

Moderator: Abdullah Sultan (KFUPM)

Panelists:

Oliver Mullins (SLB)

Maarten de Hoop (Rice University)

Milind Deo (University of Utah)

Saad Mutairi (Saudi Aramco)

Zain Yamani (KFUPM)

09:30 - 10:30

Production Chemicals Breakout

Discussion Leaders: Bastian Sauerer (SLB)

Sibani Biswal (Rice University)

10:30 - 11:30

Organic Solids Breakout

Discussion Leaders: Ahmed Moge Ali (SLB)

Dr Simon Davies (Worley)

11:30 - 13:30

Lunch & Poster Session

13:30 - 14:30

Scales & Corrosion Breakout

Discussion Leaders: David Yue (Halliburton)

Gordon Graham (Scaled Solutions Ltd)

14:30 - 15:30

Multiphase Flow Breakout

Discussion Leader: Muhammad Arsalan (Saudi Aramco)

Mohammad Aziz Rahman (TAMUQ)

15:30 - 16:30

Wrap-up Session

Session Details

SESSION ON PRODUCTION CHEMICALS

Production Chemicals for Enhanced Flow Assurance – Harnessing the Power of the Digital Space and the Molecular Scale

The design, development, and optimization of production chemicals play a crucial role in mitigating various flow assurance challenges, such as hydrate formation, wax and asphaltene deposition, scale buildup, corrosion, fracturing fluids, and formation damage caused by drilling fluids. Similarly, the increasing demand for energy and the growing importance of environmental responsibility have made it imperative for the oil and gas industry to focus on sustainable, digital, innovative, and economical solutions in the field. This session will present the latest advancements in production chemicals, exploring innovative approaches that enhance efficiency, reduce environmental impact, and optimize costs in various applications.

Key topics to be covered in this session include:

1. Novel Production Chemicals: The discovery, synthesis, and evaluation of new production chemicals that exhibit superior performance in addressing flow assurance challenges, with a focus on their effectiveness, compatibility, and environmental impact. This includes environmentally friendly (green) production chemicals, such as biodegradable and low-toxicity alternatives, that significantly reduce environmental footprints while maintaining efficacy in flow assurance.

2. Digitalization and Data-driven Optimization: The adoption of advanced digital technologies, such as molecular modeling, machine learning, and robotics, in the application, monitoring, management, and optimization of production chemicals for improved flow assurance strategy and outcomes.

3. Integrated Flow Assurance Strategies: The adoption of holistic flow assurance strategies that synergistically combine production chemicals with other mitigation techniques, such as mechanical solutions, process control, and monitoring systems, to achieve optimal outcomes.

4. Case Studies of Cost-Effective Formulations: Real-world examples from the successful implementation of innovative production chemical solutions in various oil and gas operations, highlighting the challenges faced, strategies employed, and lessons learned. In particular, the session targets the exploration of novel production chemical formulations and application strategies that minimize costs without compromising operational efficiency or environmental sustainability.

By attending this session, participants will gain a comprehensive understanding of the latest trends and innovations in production chemicals for flow assurance. They will be equipped with valuable knowledge to make informed decisions and implement cutting-edge solutions that optimize flow assurance performance in upstream operations.

SESSION ON SCALES AND CORROSION

Scales and Corrosion in The Oil and Gas Industry

Scales and corrosion pose challenges in the oil and gas industry, causing equipment damage, reduced efficiency, and safety risks. Effective management involves risk assessment, proper design, material selection, maintenance programs, and preventive measures. The session will present the latest development, innovative approaches, and industry challenges on mitigating scale and corrosion for flow assurance in the oil and gas industry.

The key topics to be covered in this session include:

1. Scale Formation and Corrosion (Experimental, Modeling, and Data-Driven Approaches): Scale formation involves the deposition of inorganic materials on surfaces, while corrosion is the deterioration of metal due to chemical reactions. Understanding factors like water chemistry, temperature, and pressure helps manage scale issues. Various corrosion mechanisms exist, requiring effective control strategies. Modeling and simulation aid in predicting scale deposition and corrosion progression, optimizing conditions, and evaluating mitigation strategies.

2. Scale and Corrosion Monitoring and Control Techniques: Monitoring techniques are crucial to identify and assess scale and corrosion issues. Control techniques such as pigging, chemical treatments, and mechanical cleaning help remove or prevent scales and corrosion. A comprehensive approach is necessary to effectively manage scales and corrosion across production and processing operations.

3. Impact of Scale & Corrosion on Flow Assurance: Scale and corrosion can cause flow restrictions, pressure drops, reduced production rates, and potential blockages, leading to maintenance, downtime, and safety risks. These can impair heat transfer efficiency and system performance. Managing scale and corrosion is vital for uninterrupted flow, optimal operational efficiency, cost reduction, and maintaining system integrity.

4. Scale and Corrosion Mitigation (Case Studies): Case studies and cost-effective solutions for scale and corrosion mitigation in the oil and gas industry offer valuable insights to operators. By analyzing real-world scenarios, these studies provide effective strategies, lessons learned, and the performance of mitigation techniques like inhibitors, coatings, and maintenance practices.

By attending this session, participants will gain a comprehensive understanding of scales and corrosion in the oil and gas industry. The session provides insights into scale formation and corrosion, associated challenges, and effective solutions and monitoring techniques to predict and mitigate the scale formation and corrosion challenge in flow assurance.

SESSION ON MULTIPHASE FLOW

Modeling and Experimentation of Multiphase Flow: Slugging, Metering, and Transportation for Empowering the Economic, Environmental, and Digital Solutions

The proper understanding of Multiphase flow challenges and flow assurance, in connection with digital data management and ecological impact, is of great necessity for the energy industry. Effective innovative production solutions to technically challenging problems in the E&P will be the core discussion of this session.

Key topics to be covered in this session include:

1. Multiphase flow: Multiphase flow is an instantaneous flow of more than two phases (oil, water, gas, solids) from oil and gas reservoirs to production facilities, transported through pipelines and manifolds. The increased global energy demand and the development of unconventional resources augment challenges to production, transportation (including CO2 mobility), processing, and measurement of multiphase flow.

2. Multiphase Flow Modeling, Metering, and Optimization: Handling and measuring multiphase flow is far more complex than single-phase flow, thus prediction becomes a challenge. The use of advanced modeling techniques and data analytics with machine learning will help optimize the production and transport of complex fluids in a complex environment (e.g., vibration, slugging flow, flow restriction caused by scale build-up, wax, and hydrates). Additionally, the need for a Multi-Phase Flow Meter is a strategy to be considered to allow early detection of water and solids which heavily cause flow assurance problems.

3. Case Studies for multiphase flow solutions and implementations: The session will present field-ready technologies and successful innovative application of metering solutions in complex multiphase flow applications and other high-level solutions for production problems that reduce costs and maintain a high level of efficiency and sustainability.

By attending this session, participants will be more informed of the latest technological advancements related to multiphase flow, slugging, and metering for flow assurance applications.

SESSION ON ORGANIC SOLIDS DEPOSITION

Flow Hindrance Due to Precipitation and Deposition of Organic Solids

Assuring unimpeded flow from the reservoir to the refinery has a game-changing impact on field development. Unnecessary investments can be avoided when engineers can characterize and understand the fluid phase behavior controlled by the flow dynamics and production chemistry in reservoirs, wellbores, surface facilities, and flow lines. This session addresses the measurement and modeling of petroleum fluid properties and organic solids. The session will include various types of organic solids that are precipitated and deposited as a result of pressure, temperature, and compositional changes due to injection fluids, production changes and pose disruption to production and potentially well shut down.

The session will include topics related to:

1. Diagnostics for prediction and management of asphaltenes, wax, hydrates, emulsions, and sludges.

2. Strategies for mitigation and remediation of production impairment due to organic deposition.

3. Application of artificial intelligence along with digital technologies to understand, forecast, and predict production behavior along with the anticipation of unplanned shutdown due to organic solids precipitation and deposition leading to sustainability.

Session attendees will engage in a thoughtful discussion on the challenges associated with organic solids and gain a deeper comprehension of these challenges, as well as a broader appreciation of the cutting-edge methodologies available for dealing with them effectively.

PANEL SESSION

Navigating the Future of Flow Assurance: A Panel Discussion Addressing the Challenge Areas of Today and the Technology Readiness for Tomorrow

As the oil and gas industry faces mounting challenges in a rapidly evolving landscape, the need for sustainable, digital, and economical solutions in flow assurance has never been more vital. This panel session brings together a diverse group of experts from academia, industry, and technology providers to identify the key challenge areas and discuss the latest innovations and strategies in achieving efficient, eco-friendly, and cost-effective flow assurance operations.

Key themes to be explored during the panel discussion include:

1. Digital Transformation: The implementation and integration of advanced digital technologies, such as artificial intelligence, machine learning, advanced computational modeling, and robotics to optimize flow assurance operations, enhance decision-making, and enable predictive maintenance.

2. Sustainability: The integration of environmentally conscious practices and the adoption of green production chemicals, considering their effectiveness, regulatory compliance, and long-term environmental impact.

3. Economic Viability and Cost Optimization: The development and application of innovative methodologies for cost analysis, resource allocation, and risk management in flow assurance operations, emphasizing the balance between operational efficiency and cost reduction.

4. Industry Collaboration and Knowledge Sharing: The importance of fostering collaboration between operators, service providers, technology developers, and academia to promote partnerships, knowledge sharing, best practices, and the adoption of innovative, sustainable, and cost-effective flow assurance solutions.

5. Hydrogen Economy: The growing market of hydrogen as a source of clean energy comes with critical challenges associated with its production, storage, and transportation. Multiphase flow can be difficult to control considering problems like corrosion, erosion, cavitation, diffusion into metals, and vibration.

By attending this panel session, participants will gain valuable insights into the key challenge areas in flow assurance and potential innovative solutions that promote sustainability, digitalization, and cost optimization.

BREAKOUT SESSIONS

Key Challenges: Identification, Ranking, and Potential Methodologies

This Symposium will present four breakout sessions focused on pressing challenges in Flow Assurance in O&G production. These interactive sessions aim to bring together experts, stakeholders, and technology innovators to identify, rank, and discuss critical issues currently faced in the realm of Production Chemicals, Organic Solids, Scales & Corrosion, and Multiphase Flow. At these breakout sessions, attendees will engage in dynamic conversations with like-minded professionals in the E&P sector.

Discussion leaders, both seasoned professionals from the E&P industry, will guide the conversation and facilitate a lively exchange of ideas, experiences, and potential venues for mitigation at each of these breakout sessions. Each session will be structured into three key segments:

1. Identification of Challenges: Participants will brainstorm and identify the most pertinent challenges in the field. Issues may range from environmental concerns, operational difficulties, regulatory compliance, cost-effectiveness, novel applications, and more.

2. Ranking of Challenges: Attendees will collaborate to rank the identified challenges based on their perceived impact, urgency, and potential for industry-wide disruption. This ranking process will provide valuable insights into the prioritization of resources and attention toward addressing these challenges.

3. Discussion and Solution Exploration: In the final segment, participants will engage in an open dialogue to discuss potential strategies, best practices, and potential innovative methodologies to address some of the top-ranked challenges. The goal is to foster industry-academia collaborations and knowledge-sharing to drive progress and improvement in the field.

By attending any of the breakout sessions, participants will gain a comprehensive understanding of the current landscape of the subject area of the session, deepen their knowledge of the most pressing challenges, and contribute to shaping the future of the industry. The breakout sessions will conclude with a wrap-up session to highlight the takeaways from the symposium and summarize to all attendees the key challenge areas in Flow Assurance.

Short Course - February 17th

Asphaltene Flow Assurance, Viscous Oil and Tar Mats Treated Within a Single Framework

Crude oils consist of dissolved gases, liquids and dissolved solids, the asphaltenes. The fractions of these three phases control many properties of crude oil that have a major impact on production. The fraction of asphaltenes in an oil is controlled by both crude oil maturity (and source rock) and by asphaltene-rich fluid transport and accumulation at various locations in the reservoir. In turn, these currents are governed by asphaltene instability from complex charge. Asphaltene instability also gives rise to flow assurance problems.

All of these complexities can be understood in a unified treatment of asphaltenes in crude oil. The Yen-Mullins codifies the nanostructures of asphaltenes in crude oil. a simple modified polymer solution theory, the Flory-Huggins-Zuo equation of state accounts for equilibrated states of asphaltenes in reservoirs as large as 50 km length scale. The new discipline “reservoir fluid geodynamics” accounts for fluid processes in reservoirs over geologic time that lead to or preclude equilibrium. Many different reservoirs from around the world including Saudi Arabia are shown to adhere to simple underlying principles. Workflows are presented to duplicate these analyses in the ‘next’ reservoir.

Course Outline:

a. Yen-Mullins Model; dominant asphaltene molecular and hierarchical nanocolloidal structures

b. Bulk properties and the Flory-Huggins-Zuo EoS

c. Structure-function relations of asphaltenes at the oil-water interface

2. Reservoir Fluid Geodynamics; a new discipilinea. compositional redistribution & phase change from charge to present day

b. Mass transport in reservoirs over geologic time

c. Processes that lead to asphaltene instability and asphaltene transport

3. Reservoir Case Studiesa. Charge history and asphaltene onset pressure

b. Asphaltene instability migration, accumulation, viscous oil and tar mats

c. Treatment of asphaltene deposition

Course Instructor:

Dr. Oliver C. Mullins is a SLB Fellow and member of the U.S. National Academy of Engineering. He initiated and is leading the new discipline, “reservoir fluid geodynamics” (RFG), which accounts for fluid compositional redistribution and phase changes during and post charge over geologic time. RFG is focused on reservoir evaluation and utilizes Downhole Fluid Analysis which he initiated and asphaltene thermodynamics which his team developed. He wrote and co-edited 5 books, and coauthored 17 book chapters. He contributed to 300 publications and coinvented 143 US patents. He has 28,000 citations on Google Scholar. He has received seven international awards from four organizations (ACS, SPE, SPWLA, ADIPEC) including the Anthony F. Lucas Gold Medal from the SPE and the George A. Olah Award in Hydrocarbon or Petroleum from the American Chemical Society.

Program Summary

Feb. 17,2024

SHORT COURSE

8:00 - 11:30

ASPHALTENE FLOW

ASSURANCE:

Reservoir Fluid

Geodynamics with

Case Studies

Feb. 18,2024

OVERVIEWING TECH

INNOVATIONS

8:00 - 8:30

Introduction

8:30 - 10:00

Production Chemicals

10:00 - 11:00

Organic Solids

11:00 - 11:30

Opening Ceremony -

Dr. Muhammad Al-Saggaf,

KFUPM President

11:30 - 13:30

Lunch & Poster Session

13:30 - 15:00

Scales & Corrosion

15:00 - 16:30

Multiphase Flow

Feb. 19,2024

IDENTIFYING

CHALLENGE AREAS

8:00 - 9:30

Panel Session

9:30 - 10:30

Production Chemicals

Breakout

10:30 - 11:30

Organic Solids

Breakout

11:30 - 13:30

Lunch &

Poster Session

13:30 - 14:30

Scales & Corrosion

Breakout

14:30 - 15:30

Multiphase Flow

Breakout

15:30 - 16:30

Wrap-Up Session

Mazen Kanj

CPG-KFUPM Consultant